Goldline

SAFEsolutions

Additional product detail to help you identify the exact solution you need for your project, personnel safety, or to improve operational performance.

Loading Rack Platforms

Type 1 Loading Platform

Type 1 Loading Rack Platforms are designed to give access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars.

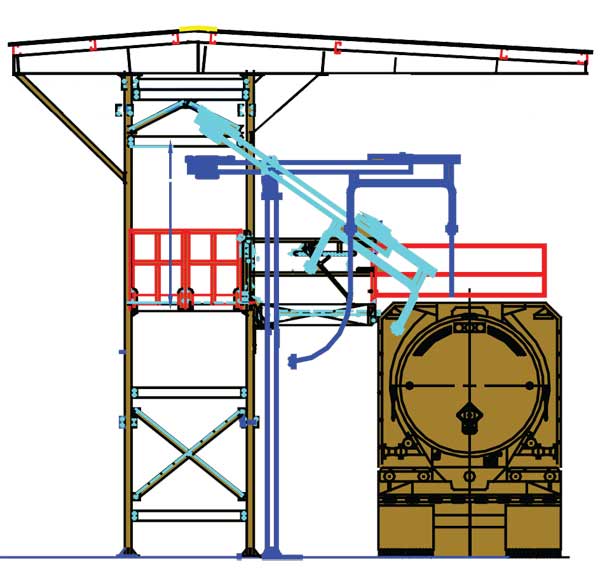

Type 2 Loading Platform

Type 2 Loading Rack Platforms are designed for access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars, with overhead pipe support.

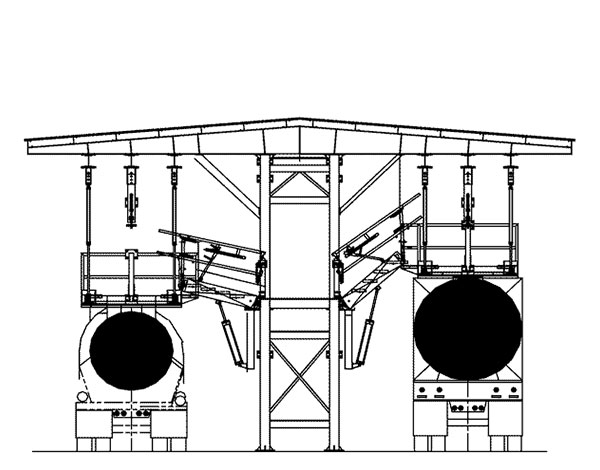

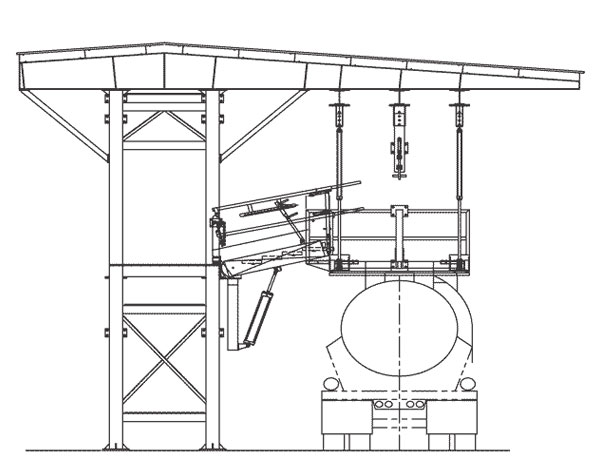

Type 3 Loading Platform

Type 3 Loading Rack Platforms are designed for access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars.

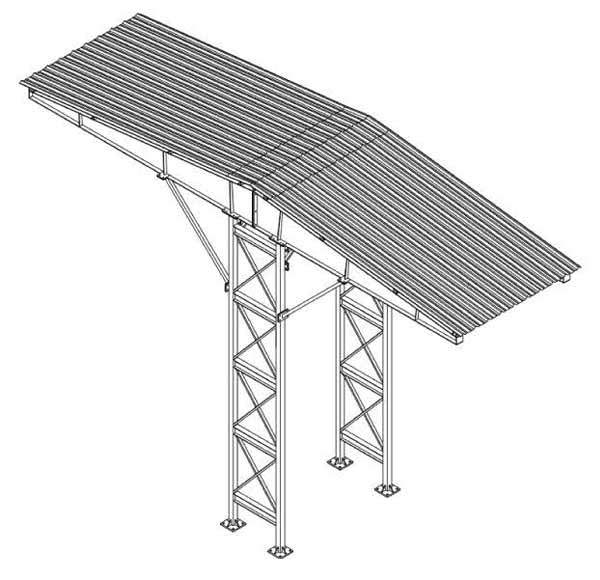

Type 4 Loading Platform

Type 4 Canopy can cover anything from electrical panels to pedestal loading racks.

MORE

Goldline loading rack platform comply with OSHA regulations and are accessed by an industrial type stairway or fixed ladder with self-closing gate.

The Type 1 column frame support provides excellent stability for larger safety cages and pneumatics and can easily be extended to accomodate multiple loading spots for Rail Cars and Tank Trucks.

MORE

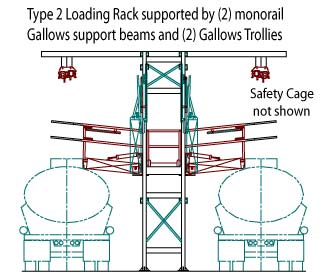

A 3′-0″ wide walk platform and a fixed industrial stairway for easy access. Extra features for this Loading Rack include the overhead Pipe Support Panel. An optional Monorail system may be added. The Type 2 allows the option of adding a canopy at a later date.

MORE

This Loading rack includes a full canopy, available with side weather walls, gutters, and downspouts and shelters with HVAC and heater along with complete electrical packages available for Class 1, Div 1 or Div 2 work environments.

Canopy panels come in 26 gauge Galvalume with custom colors.

Canopies are useful in keeping operators and product dry in rainy and snowy conditions, and for additional operator safety in wet contitions.

MORE

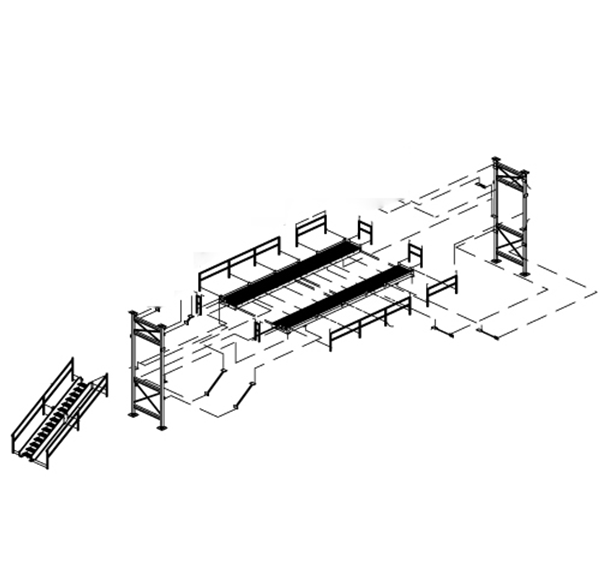

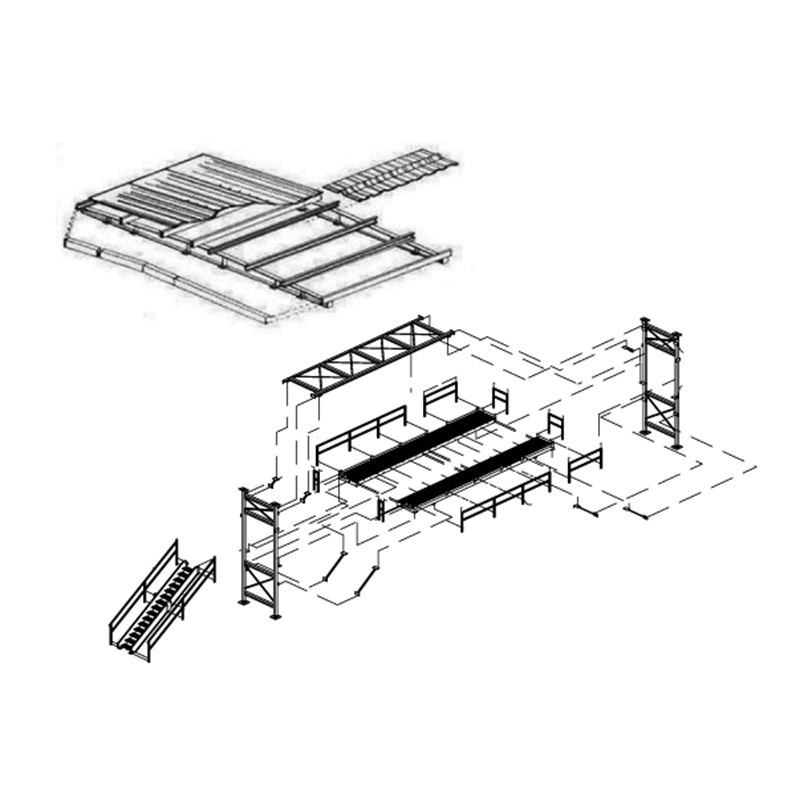

The Goldline “FASTERECT” Loading Rack Systems, fast, safe, bolt together components, available in four types.

A stand alone canopy is best where truck or rail car is bottom loaded or unloaded or electrical. Optional features include: side weather walls, gutters and downspouts.

Canopy panels are 26 gauge Galvalume, custom colors are available.

Canopies are useful in keeping operators and product dry in rainy and snowy conditions, and for additional operator safety in wet conditions.

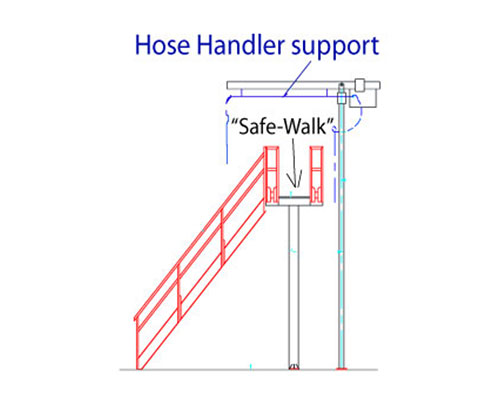

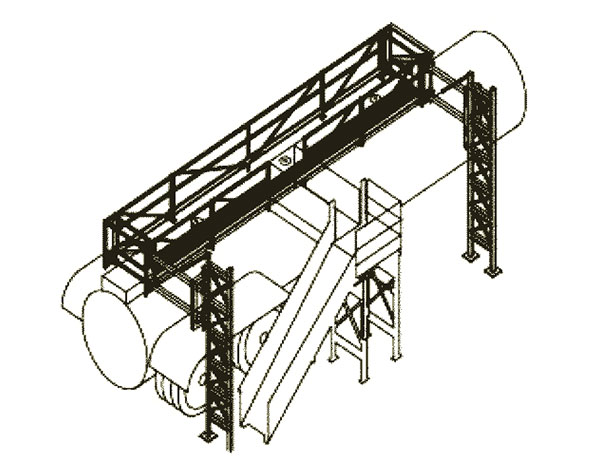

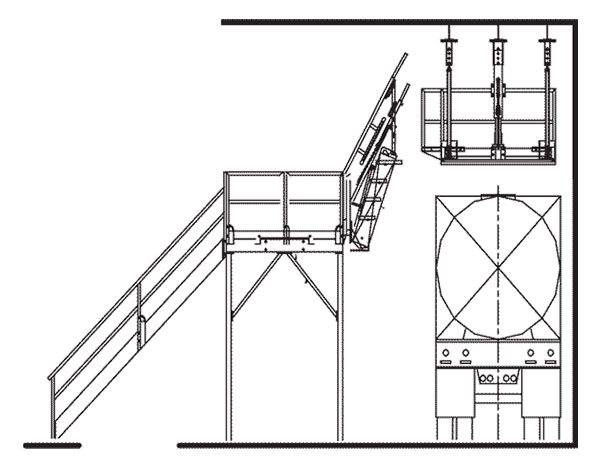

Type 3.5 Loading Platform

Goldline Type 3 1/2 Loading Racks are designed to access vehicles on one side.

Both Rail Cars and Tank Trucks can be accessed easily and safely.

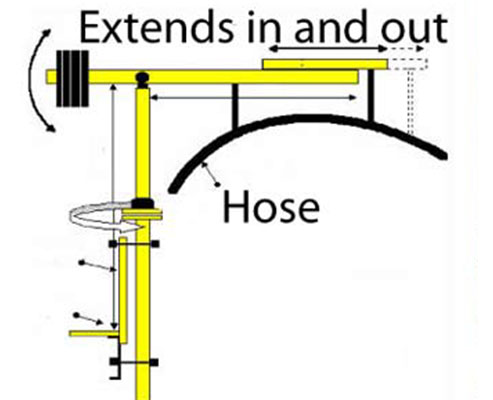

Drawing of a Type 3 1/2 Loading Rack with a Single Beam Hose Handler.

Custom Loading Rack Platform

Goldline has many loading rack options. We can design and build a loading rack to meet your needs.

To get started on your own loading rack simply fill out the form at the bottom of this page or give us a call. Nothing outperforms Goldline.

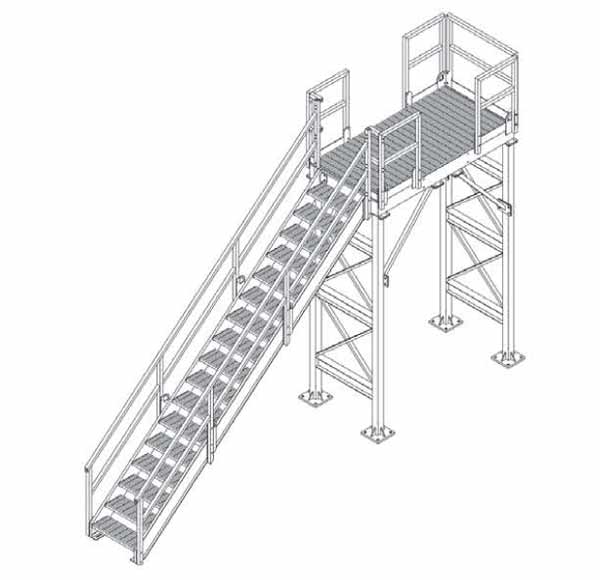

Fast-Erect™ Loading Rack System

Goldline has many loading rack options. We can design and build a loading rack to meet your needs.

To get started on your own loading rack simply fill out the form at the bottom of this page or give us a call. Don’t be fooled by other loading platforms. Nothing outperforms Goldline.

MORE

Side weather walls are available with down spouts and gutters. Side weather walls, downspouts, and gutters help keep rain water out of containment areas and help keep surfaces dry to prevent slippage.

With Goldline’s ISO Walkways, your Type 3 1/2 canopy package is complete. The standard ISO Walkways are 8’ – 0” long to 16’ – 0” long.

Loading Racks come in all shapes and sizes, we build to suit your requirements.

MORE

The more frequently used designs have been standardized as “Class A”. Those used to meet special conditions are “Class B”.

“Class A” and “Class B” Loading Racks can be provided with a complete AutoCAD design package that meets or exceeds the requirements of the geographical area in which the project will be located.

Mobile Loading Rack Platforms

Mobile Loading Platform

The Goldline Mobile Loading Platform is designed to be a Portable Mobile Loading station for access to all types of vehicles.

Tow bars are used to move all mobile units. A mobile loading platform is one option for closing or opening hatches at a plant entrance or exit to reduce foundation cost.

Small Mobile Platform

Small Mobile Loading Platform units are easily moved and can provide quick access to hard-to-access areas in small spaces.

These can be can be moved by hand or moved with a truck or similar vehicle utilizing built-in tow bars.

Mobile Personnel Safety Platform

Goldline’s smaller MAP units make excellent personnel safety platforms. They can quickly and easily be moved into any area, providing quick or temporary access to area that may be hard to access.

MORE

A variety of Goldline Safe-walk™ units and Safety Cages can be used with these mobile units.

Goldline repairs our equipment in the field on demand, while also providing Service Policies to maintain our equipment.

MORE

A variety of Goldline “Safe-walk” units and Safety Cages can be used with these mobile units.

The small Mobile MAP unit can be moved by hand and the heavy duty Mobile Loading Racks can be moved with a truck or similar vehicle.

MORE

Smaller MAP units can be deployed anywhere, but are primarily used in warehouse environments or to access a side of tank trucks.

All of these units are custom built to customer specifications.

Pedestal Loading Rack Platforms

Single Pedestal

For access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars.

A single working platform.

Dual Pedestal

For access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars.

Two working platforms.

Triple Pedestal

For access to Tank Truck, ISO Container Truck, Hopper Truck, and Rack Rail & Hopper Cars.

Three working platforms.

Pedestal Options

The Goldline Pedestal Platforms can become a part of larger, interconnected systems. They can also have added:

-

-

- Hose Handlers

- Safety Cages, Hoops

- Safe-Walk Walkways

- Canopies

-

Safety Cages

All safety cages are built to meet individual customer requirements. Please contact our sales department to understand how the Goldline Safety Cages can improve the safety and performance of your operation.

Vertical Lift Cage

With parallel arms.

Vertical Lift Cage

Column support, Type 1, with Access Platform

Vertical Lift Cage

Double sided, Type 3, and Canopy

Vertical Lift Cage

Single sided, Type 3, Half Canopy

Cantilevered Safety Lift Cage

Double Hoop Safety Cage

Hose Handlers

Hose Handlers are typically used to access the top of Rail Cars or Tank Trucks.

Goldline Single Beam Hose Handler: with extendable boom that pivots up and down. The counter weighted boom is 12′ 4″ long and will adjust out to 13′ 11″ fully extended. Manually operated, the 6″ stand pipe riser is located approximately 7′ 6″ above the loading rack platform and attaches to the platform and bolts onto the foundation.

This unit will handle one or two hoses (product hose and vapor hose). The standard finish is galvanized, except the dry swival is prime coated. Goldline also can furnish a special cradle type hose handler that can handle up to six hoses. Our Hose Handlers also have Pneumatic and Hyrdraulic support packages.

Full Range of Motion

Quick Installation

Easy, Safe Access

Gallows Fall Safety Protection

Goldline’s Fall Protection system is designed for personnel to operate safely in a production area, rated to meet or exceed a 5000 pound load per person.

When necessary, Goldline can operate with plant safety staff in setting up a training session and enforcement procedures and work with our customers in complying with or exceeding OSHA and other local safety codes. Our sales staff is trained to work with plant safety officials in finding and eliminating potential threats in making all work environments as safe as possible.

Sometimes plants have difficulty enforcing the safety policy of 100% tie off to a Fall Protection system. In that case, Goldline does communicate where enforcement to 100% tie off to an overhead Fall Protection system is not possible 100% of the time, in these cases Goldline has a complete line of safety cages that can be built to individual plant requirements.

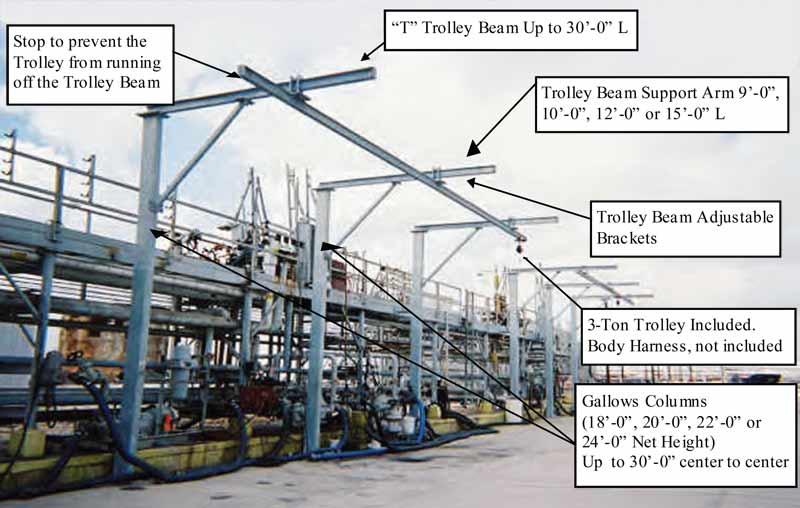

Trolley Beams Gallows Fall Protection

Trolley Beam

Gallows Fall Protection

Type 2 Loading Rack

With Safety Gallows Fall Protection

For many plants, a Gallows Fall Protection system is a good fit. With a rigorous safety program that awards those who wish to remain conscientious of their work environment to remain safe, a Gallows Fall Protection system gives the operator freedom of movement.

One consideration that must be reviewed before a Goldline Gallows Fall Protection system is used is that Goldline International LLC and OSHA agree that tie off must be no less than 7′-6″ or more overhead. This most conservative limit for overhead tie off is meant to allow the Goldline 100% tie off Fall Protection system time to engage and prevent an: incident, injury, or death. Many locations have obstructions preventing a Goldline Gallows Fall Protection system time to engage in a timely manner. Then, Goldline safety cages must then be reviewed in that instance.

Goldline stands ready to visit your location and will do a free site walk through of your business. If you would like us to visit your facility anywhere in the USA Goldline International site visits are normally free of charge. We also take pride that our products are 100% American Made.

The Fast-Erect Loading Platform Advantage

Goldline’s Fast-Erect bolt-together loading rack system is designed to provide a safe, quick assembly system for field installation that allows the customer to control field erection time and cost.

The Fast-Erect design saves time and money because of its modular approach to SAFEsolution structures and components.

Goldline Protects Your Investments

CLICK TO SEE OUR REPAIR OPTIONS

Maintenance and Repair—

- We offer monthly, quarterly and annual maintenance programs for minimal downtime and overall cost savings

- Routine maintenance can be performed on your site

- Repairs are typically performed in our facility

- Depending on the product purchased, expedited replacement units may be available

"Safe-Walk Field Service and Maintenance—

Goldline "Safe-Walk" units are easy to service and maintain. We also repair nautical gangways.

You have a project. We have a solution.

Please fill out the form and one of our experts will be in touch with you shortly.

We look forward to working with you to exceed your expectations while you lower risk in your high-risk environments.

Serving the Marine, Rail, Petrochemical, and Construction Industries since 1973.

![]()

![]()

![]()

![]()

Setting the Standard.

Explore how you can reduce your project and ongoing operational risk with Goldline International.

Explore

© Goldline International, LLC | Legal and Privacy

sales@goldlinesafewalk.com | Call Now: 800-722-1608 or 713-475-1201