Standards, Codes, Quality, and Designs

Our Fabrication Standards

and Code Compliance

Our products and equipment are designed, engineered, and manufactured to meet or exceed the following requirements, codes, and standards. Click on any of the logos to go to the organization’s website.

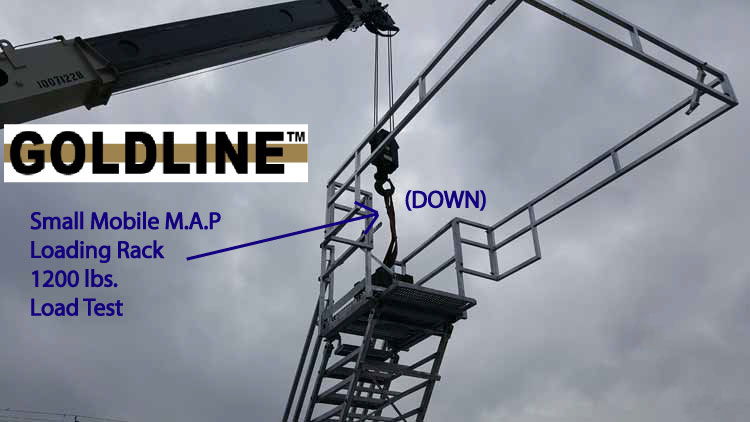

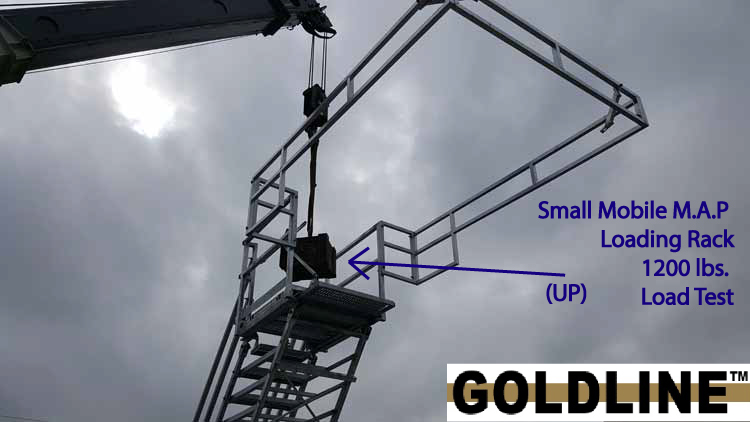

Testing and Quality Control

Goldline International manufactures all our equipment and products at our location in Pasadena, Texas. We’re proud to have all our products made in the USA.

Our patented, modular “Fast-Erect” bolt-together Loading Rack System was designed to provide a safe, fast system for field erection that allows the customer to easily control field erection time and cost. The “Fast-Erect” System allows a customer to estimate the assembly cost and schedule more accurately for quicker and less expensive installations.

All our products are bolted together and tested for fit, finish, and functionality before shipping to the customer site.

We follow our GOLDprocess for every project and customer. This means you get:

-

-

-

- Fast turnaround on customer quotes and drawings, when requested

- Accurate order entry for every customer order

- To approve all drawings before manufacturing, as needed

- To approve every project step with fast order processing

- Shop drawings that ensure correct cuts and fabrication

- To assist determining shipping schedule that meets the your needs

- A detailed shop schedule for your project

- Our committment to order and receive materials in a timely fashion

- Our committment to cutting steel according to the cutting schedule

- Component and parts fit-up, according to the shop fabrication drawings

- Expert welding out of all parts and assemblies

- Thorough inspection of all welds and connections

- Additional Quality Assurance Fit-up of all component parts to ensure proper fabrication and fit

- No-hassle galvanizing, as required

- Complete assembly drawings to help in your installation

- Timely shipping of your equipment or product as agreed

-

-

Additionally, at your option

-

-

-

- Installation at your site according to your specifications

- Maintenance programs that maintain safety and operational performance

-

-

Our overall customer service and manufacturing sets Goldline apart as being the best in safety. Our equipment is used in multiple industries, including: refining, petrochemical, food processing and asphalt industry.

Goldline is celebrating 50 years in Pasadena, Texas. We are one of the senior fall protection advisors in the USA. After decades of service to the fall protection industry, we continue to improve safety in our equipment and the industry.

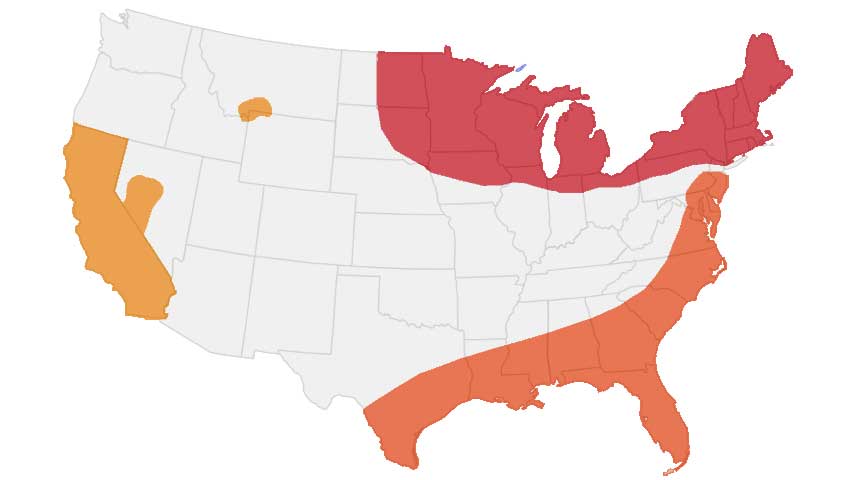

Loading Rack Design Regions

Design Region 1 (light orange)—

-

-

- 0-25 PSF Snow Loads

- 20 PSF Live Load on Canopy + 10 PSF Deadfall (IBC)

- 110-115 MPH Wind Load on Structure

- 125 PSF Live Load on Platform

-

Design Region 2 (red)—

-

-

- 20-100 PSF Snow Load on Canopy

- 115-140 MPH Wind Load on Structure (IBC 2015)

- 125 PSF Live Load on Platform

-

Design Region 3 (gray)—

-

-

- 0-40 PSF Snow Load

- 20 PSF Live Load on Canopy (IBC)

- 115 MPH Wind Load on Structure

- 125 PSF Live Load on Platform

-

Design Region 4 (orange)—

-

-

- 0-30 PSF Snow Load

- 115-180 MPH Ultimate Wind Load on Structure

- 125 PSF Live Load on Platform

-

Click here to obtain a PDF download of the report and map

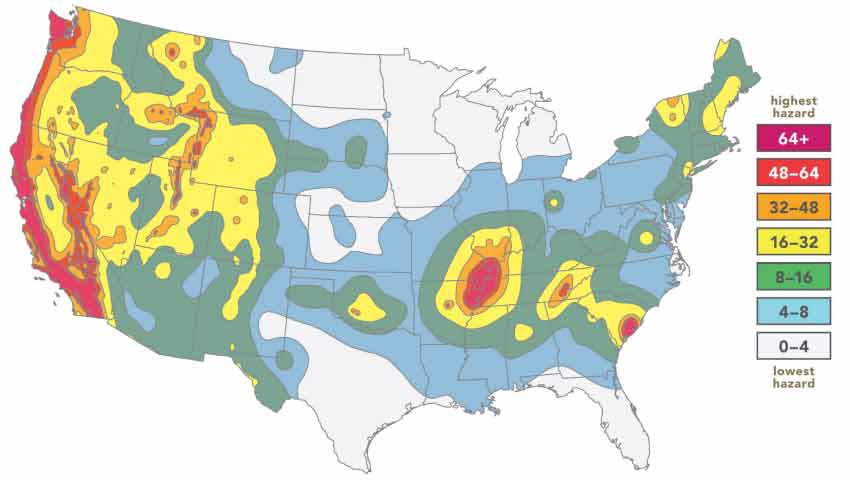

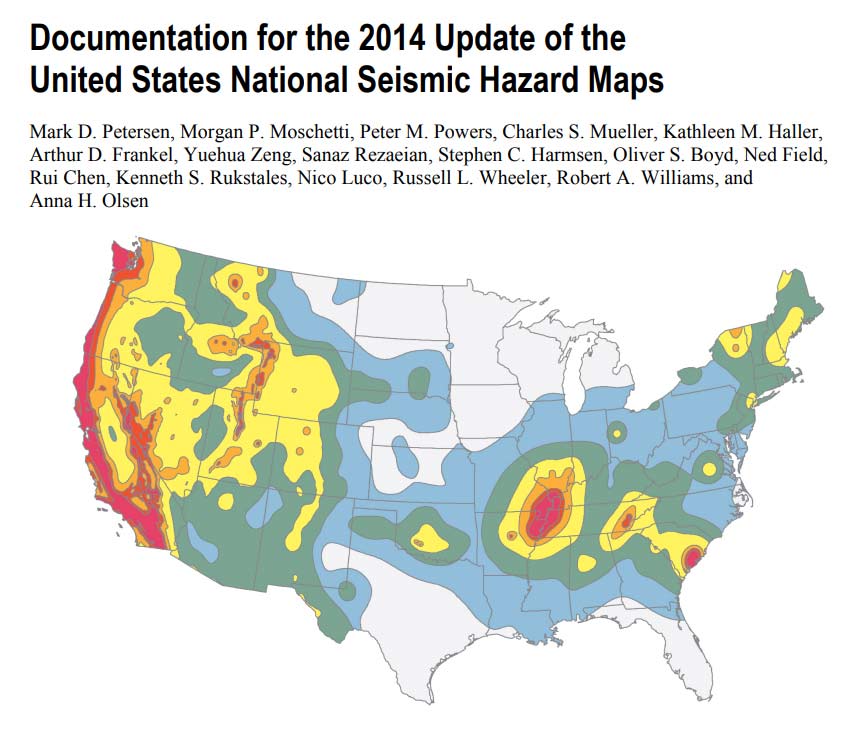

Please note:

These time-independent maps are shown for 2-percent and 10-percent probability of exceedance in 50 years for peak horizontal ground acceleration as well as 5-hertz and 1-hertz spectral accelerations with 5-percent damping on a uniform firm rock site condition (760 meters per second shear wave velocity in the upper 30 m, VS30).

In this report, the 2014 updated maps are compared with the 2008 version of the maps and indicate changes of plus or minus 20 percent over wide areas, with larger changes locally, caused by the modifications to the seismic source and ground motion inputs.

[Abstract: Page 13]

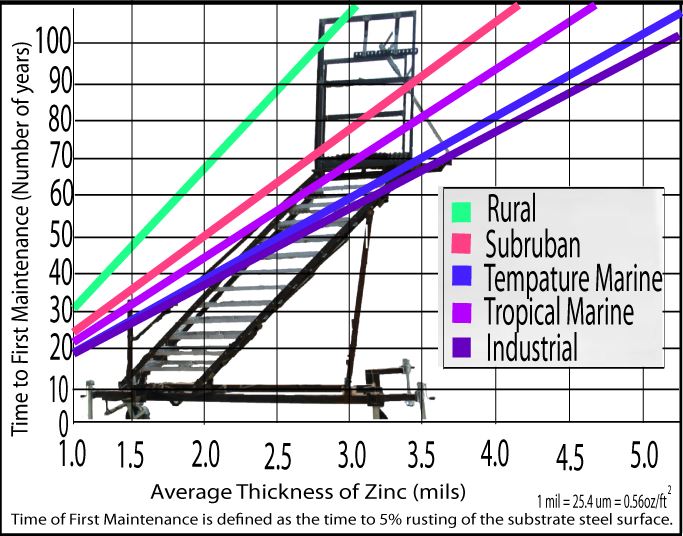

Corrosion Protection Standards

Black Iron or Hot Dipped Galvanized?

When working in harsh environments the quality of corrosion protection is an important part of the decision making and product design process.

Many competitors offer their products in black iron, aluminum, or other materials, each with their own corrosive properties.

At Goldline we offer our products in either black iron or hot dipped galvanized options—with a preference for galvanized corrosion protection!

Hot dipped galvanizing provides year, or decades, of corrosion protection before your first maintenance event. Whether in years or decades, time is measured by the thickness of the zinc coating in the clean galvanizing process.

The chart on this page shows 5.0 galvanizing zinc coating thickness can produce up to 98 years of very low finish maintenance.”

Goldline highly recommends hot-dipped galvanized!

Additional Helpful Information

You have a project. We have a solution.

Please fill out the form and one of our experts will be in touch with you shortly.

We look forward to working with you to exceed your expectations while you lower risk in your high-risk environments.

Serving the Marine, Rail, Petrochemical, and Construction Industries since 1973.

![]()

![]()

![]()

![]()

Setting the Standard.

Explore how you can reduce your project and ongoing operational risk with Goldline International.

Explore

© Goldline International, LLC | Legal and Privacy

sales@goldlinesafewalk.com | Call Now: 800-722-1608 or 713-475-1201